Superior Performance & Finishes

1. Selecting high-quality manufacturing materials to lay a solid foundation for product quality

Materials are the core foundation of product quality. We adhere to the principle of "high standards, high safety, and high durability" in material selection. All raw materials undergo multiple rounds of screening and testing to ensure that the product quality is guaranteed from the very beginning, perfectly meeting the strict requirements of customers for materials.

Main material: High-quality brass and 304 stainless steel

The main body of the faucet is primarily made of 59-1 lead-free brass, with the lead content far lower than the 0.25% limit stipulated by the US Safe Drinking Water Act (SDWA), effectively preventing secondary pollution of drinking water and ensuring the safety of users' water supply. This material has excellent corrosion resistance and wear resistance. It shows no rust after being tested with salt water for over 480 hours. Even when used in damp bathrooms or kitchens for a long time, it can maintain stable performance, extend the product's lifespan, and meet the expectations of American families and commercial establishments for product durability.

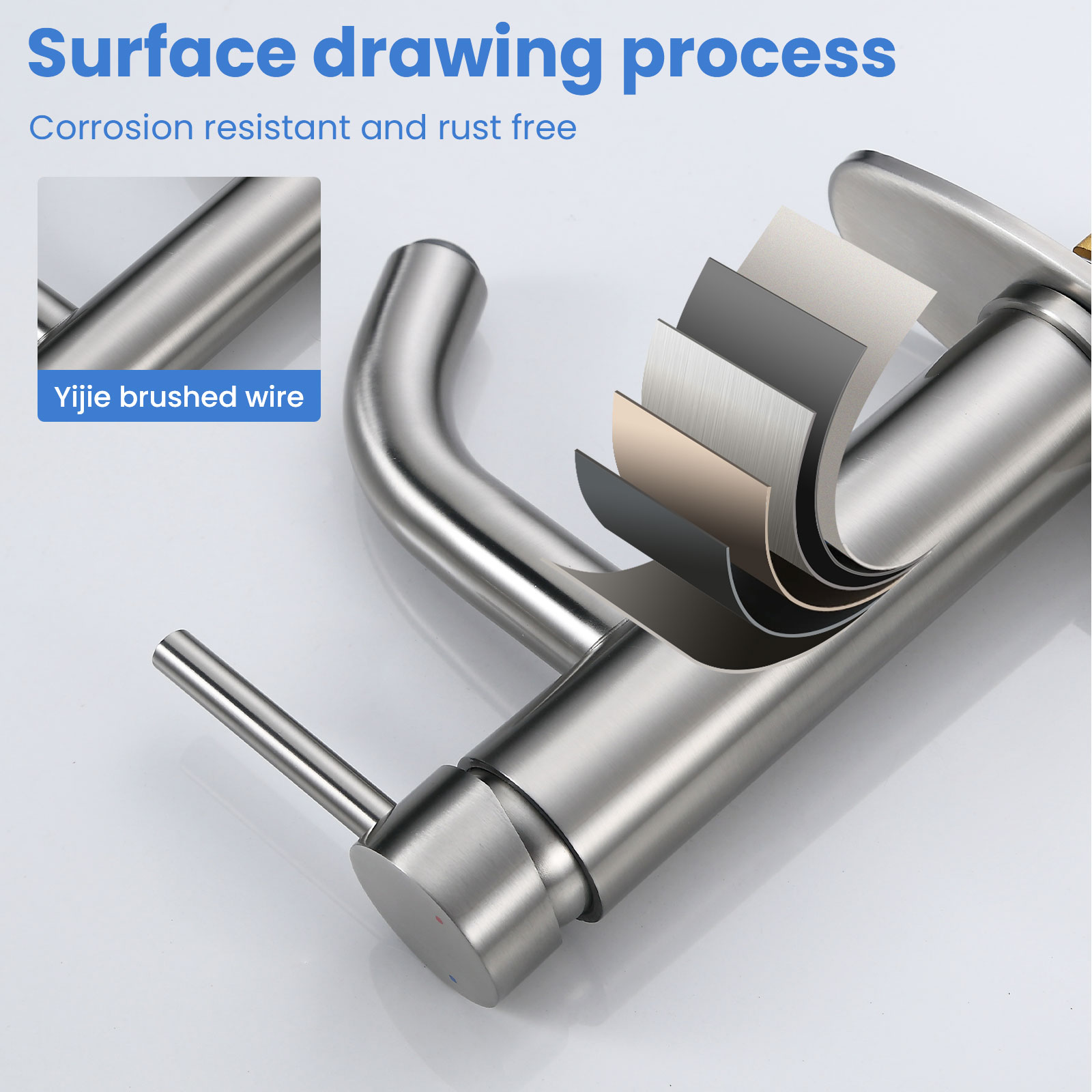

Some products use food-grade 304 stainless steel, which contains no harmful substances such as lead and nickel. It has passed the NSF/ANSI 51 food equipment material certification. It not only has outstanding corrosion resistance and rust prevention capabilities, but also has good toughness and processing performance. It can meet different design requirements and is compatible with the safety standards for food-contact products in the United States, suitable for scenarios such as kitchens and those related to food.

Surface treatment materials: Eco-friendly coating and wear-resistant coating

The surface coating uses multi-layer PVD (Physical Vapor Deposition) technology materials, including chromium, nickel, copper, etc., which are environmentally friendly metals. The coating thickness is uniform and reaches 8-12 micrometers, far exceeding the requirements of the American ASTM B456 standard. This material has extremely strong adhesion. After 20,000 times of wear resistance tests, there are no scratches, and it has passed the American EPA environmental certification. It does not contain harmful heavy metals such as hexavalent chromium. During use, it does not release toxic substances, balancing aesthetics and environmental protection, meeting the dual needs of American customers for the durability and greenness of product appearance.

Special scene products (such as outdoor faucets) additionally add fluorocarbon coating, which has excellent resistance to ultraviolet rays and aging. After 1,000 hours of ultraviolet radiation tests, there is no fading or cracking, and it can adapt to the extreme climates of different regions in the United States, ensuring that the product remains stable and durable in the outdoor environment exposed to sun and rain.

Sealing and valve core materials: High-performance sealing components and ceramic valve cores

The sealing components use food-grade silicone rubber and EPDM (Ethylene Propylene Diene Monomer) rubber, which have passed the American FDA food contact certification. They are resistant to high temperatures (-50°C - 200°C) and aging, have excellent sealing performance, and have undergone 500,000 times of switching tests without leakage. This effectively avoids water leakage caused by sealing failure and reduces water waste, conforming to the American concept of water conservation.

The valve core selects high-quality ceramic valve cores with a hardness of over HV1100 and a surface finish of Ra0.02 μm. After 1 million times of opening and closing tests, the flow error is still controlled within 5%, far exceeding the requirements of the American ASME A112.18.1 standard, ensuring the smooth and stable operation of the faucet over a long period, and reducing the maintenance costs for customers.

II. Precise Core Manufacturing Techniques, Creating Superior Product Performance

Relying on advanced production equipment and a mature process system, we will achieve the ultimate perfection in every process detail. Through meticulous processing and strict quality control, we endow the products with outstanding performance and stable quality, fully meeting the high requirements of American customers for product craftsmanship.

Precision Casting Process: Integrated Forming, Eliminating Structural Hazards

Using the lost-wax precision casting process, the yellow copper raw materials are subjected to high-temperature melting (with the temperature controlled at 1080℃ - 1120℃), and then precisely molded through molds to achieve integrated manufacturing of the faucet body, avoiding defects such as pores and cracks that may occur during the welding process. The cast products undergo X-ray flaw detection to ensure that the internal structure is free of impurities and sand holes, with a strength of over 250MPa, in line with the American ASTM B62 standard, capable of withstanding long-term high-pressure water flow impact, and eliminating the risk of fracture or leakage due to structural issues.

Numerical Control Processing Process: Precise Control of Dimensions, Enhancing Assembly Precision

Introducing a five-axis联动 numerical control processing center, we perform high-precision processing on the cast products. The processing accuracy can reach ±0.01mm, and we strictly control key parameters such as interface dimensions and thread accuracy in accordance with the American ANSI/ASME B16.5 standard to ensure seamless assembly between the faucet and pipes, fittings, and reduce installation difficulty. At the same time, it avoids leakage problems caused by size deviations. During the processing, each process is equipped with online detection equipment to monitor product dimensions in real time, ensuring that every product meets the standards.

Surface Treatment Process: Multi-layer Protection, Balancing Beauty and Durability

The surface treatment adopts a "pre-treatment - electroplating - glazing" three-stage process: In the pre-treatment stage, through chemical degreasing, acid washing, and passivation steps, the oil stains and oxide layers on the product surface are completely removed, enhancing the adhesion of the coating; in the electroplating stage, a multi-layer electroplating process is adopted, first plating copper (thickness 5-8μm) as the base layer, then plating nickel (thickness 8-12μm) to enhance corrosion resistance, and finally plating chrome (thickness 0.2-0.5μm) to improve surface smoothness and wear resistance; in the glazing stage, an environmentally friendly glazing layer is sprayed to further enhance surface anti-stain and anti-fingerprint performance. The entire surface treatment process undergoes SGS environmental testing, in line with the strict restrictions of California Proposition 65 (Prop 65) on the release of harmful substances, with a surface gloss of over 90°, and the product surface is not prone to staining or fading over a long period of use, maintaining a beautiful appearance.

Safety and Environmental Certification: Ensuring User Health and Aligning with Green Concepts

NSF/ANSI 61 Certification: Certified by the National Sanitation Foundation (NSF), this certification proves that the product will not release harmful heavy metals such as lead, mercury, and cadmium during contact with drinking water, meeting the safety requirements for water-related products stipulated in the US Safe Drinking Water Act, and ensuring the health of users' water consumption.

California Proposition 65 Certification: The product has passed the California Proposition 65 test, with the content of all harmful chemical substances (such as phthalates, formaldehyde, etc.) in the materials being lower than the limit specified in the proposition. It can be legally sold in California and other regions of the United States, avoiding legal risks due to environmental protection issues.

EPA Environmental Certification: The raw materials and processes used in the production of the product comply with the environmental protection requirements of the US Environmental Protection Agency (EPA), with the production wastewater and exhaust gas being treated and discharged up to the standard. At the same time, the product's recyclability rate reaches over 80%, aligning with the US sustainable development concept and meeting customers' demands for environmentally friendly production.

Water-saving Certification: Responding to water-saving policies and reducing usage costs

WaterSense Certification: The product has passed the US EPA WaterSense water-saving certification. The kitchen faucet flow rate is ≤ 1.5 GPM (gallons/minute), the bathroom faucet flow rate is ≤ 1.2 GPM, and the shower faucet flow rate is ≤ 2.0 GPM. Compared to traditional faucets, the water-saving rate is over 30%, and it ensures that the water pressure and usage experience are not affected while saving water. Products with this certification can help American customers reduce water expenses and comply with the water-saving policy requirements of some US regions (such as California, New York State, etc., which have mandatory procurement regulations for water-saving products), enhancing the product's competitiveness in the market.

Performance and Quality Certification: Demonstrating Reliability and Reducing售后 Risks

ASME A112.18.1 Certification: Certified by the American Society of Mechanical Engineers (ASME), this certification covers multiple aspects such as the structural strength, sealing performance, flow stability, and durability of the faucet. The product must undergo 1 million opening and closing tests, 480 hours of salt spray tests, etc., to prove its stable performance and reliable quality, meeting the long-term usage needs of commercial and civilian places in the US and reducing customer maintenance costs.

CSA B125 Certification: Obtained from the Canadian Standards Association (CSA), this certification is mutually recognized with the US ASME standard, meaning the product not only meets the requirements of the US market but can also enter the Canadian market simultaneously, providing convenience for customers to expand the North American market. At the same time, the certification covers the electrical safety (for smart faucets) and mechanical performance of the product, ensuring the safety and stability of the product in different usage scenarios.

Industry Compliance Certification: Meeting Market Entry Requirements and Ensuring Smooth Trade

FDA Food Contact Certification: For products such as kitchen faucets that may come into contact with food, certified by the US Food and Drug Administration (FDA), proving that the product material will not undergo chemical reactions with food and there is no migration of harmful substances, meeting the safety standards for food-contact products in the US, eliminating customers' concerns about product safety.

UL Certification (for smart faucets): For faucets with intelligent functions such as sensing and APP control, certified by the Underwriters Laboratories (UL), ensuring that the electrical part of the product complies with US safety standards, avoiding safety accidents caused by electrical faults, and meeting the market entry requirements for smart household appliances in the US.

From materials and processes to qualifications, every effort we make is centered on meeting the needs of American customers. We not only provide customers with high-quality products that meet standards, but also offer them comprehensive guarantees through a well-developed service system, ensuring that customers can make purchases with peace of mind.

Customized Adaptation Services: We can provide customized production services based on the specific needs of American customers (such as product design, functional configuration, surface color, etc.). Relying on a flexible production system, we maintain efficient communication with customers throughout the design, prototyping, and batch production processes, ensuring that customized products fully meet customer expectations. At the same time, we strictly control the materials, processes, and qualifications of customized products to ensure that the quality is not compromised.

Comprehensive After-sales Support: We provide long-term after-sales support for American customers. All products enjoy a 5-year warranty service (some high-end products enjoy a 10-year warranty). During the warranty period, if quality issues occur due to non-human factors, customers can receive free replacement of parts or products. At the same time, we have an after-sales service center in the United States, equipped with professional technicians and sufficient spare parts inventory, which can quickly respond to customers' after-sales needs and provide on-site maintenance, technical guidance, etc., reducing customers' after-sales costs and time costs.

Transparent Supply Chain Management: We open supply chain information to American customers, allowing them to query information such as product raw material sources, production progress, and test reports at any time, ensuring that the product's entire life cycle is traceable. At the same time, we establish long-term cooperation with local logistics enterprises in the United States, providing efficient and stable logistics delivery services, ensuring that products are delivered safely and on time to the designated locations of customers, shortening the delivery cycle and improving the efficiency of customer purchases.